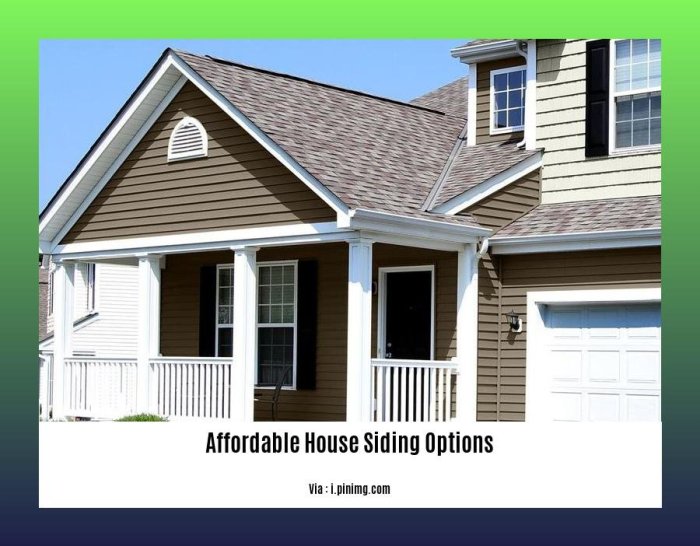

Siding Installation Cost A Comprehensive Guide

Siding installation cost is a crucial factor to consider when undertaking a home improvement project. Understanding the various elements impacting the price, from material choices to labor rates, is essential for making informed decisions. This guide will walk you through the factors influencing siding installation costs, from estimating accurately to comparing quotes and negotiating effectively. It also highlights strategies for saving money and choosing the right siding material for your needs.

This comprehensive analysis explores the multifaceted aspects of siding installation costs, encompassing material types, labor expenses, regional variations, and potential hidden costs. We’ll provide a step-by-step process for estimating costs, offer tips for comparing quotes, and detail the cost breakdown involved in a typical project. Finally, we’ll delve into the influence of local market conditions and help you make the most cost-effective choice of siding material.

Factors Affecting Siding Installation Costs

Source: inchcalculator.com

Siding installation costs are influenced by a multitude of factors, making it challenging to provide a single, definitive price. Understanding these variables is crucial for homeowners to get accurate estimates and avoid surprises during the project. This section delves into the key determinants of siding installation costs, from material selection to labor rates and regional differences.

Accurate cost estimates are vital for planning and budgeting siding projects. Homeowners need to be aware of the many variables affecting the final price to ensure they are making informed decisions.

Material Costs and Siding Types

Different siding materials have varying costs, impacting the overall project budget. The price per square foot of siding significantly influences the total cost. Factors such as material availability and demand can fluctuate, contributing to price volatility.

- Vinyl siding, often considered a budget-friendly option, typically has a lower cost per square foot compared to other materials like wood or fiber cement.

- Wood siding, while offering a classic aesthetic, usually carries a higher cost per square foot due to the material’s inherent value and the labor involved in its installation.

- Fiber cement siding presents a balance between durability and cost, with a price point generally higher than vinyl but lower than some types of wood siding.

Labor Rates and Installation Complexity

Labor costs play a substantial role in the total expense of siding installation. Skilled labor is required to ensure proper installation, which directly affects the project’s final cost. Installation complexity can significantly impact the labor time needed, thus influencing the overall price.

- Experienced installers command higher hourly rates, reflecting their expertise and efficiency.

- The complexity of the installation, including architectural features, access difficulties, and the size of the home, can affect labor time and, consequently, the final cost.

- The availability of skilled labor in a particular region can also affect labor rates, leading to regional variations in installation costs.

Regional Variations in Costs

Siding installation costs vary considerably across different regions. The cost of living, labor market conditions, and material availability all influence the overall price. This variation makes a standardized national cost estimate unreliable.

- Areas with higher living costs often experience higher labor rates, contributing to increased installation costs.

- The availability of materials in certain regions can affect the pricing of siding and installation, with supply chain issues potentially contributing to fluctuations.

- Regional building codes and regulations can impact the time required for installation and therefore, the overall cost.

Impact of Installation Complexity

Installation complexity, including house size, architectural style, and access issues, significantly affects the final cost. These factors influence the amount of time and labor required for the project.

- Larger homes require more materials and labor, resulting in higher installation costs.

- Complex architectural styles with intricate features or difficult-to-access areas often necessitate more time and labor, thereby increasing the total expense.

- Challenging access points, such as steep slopes or limited space, may require specialized equipment or techniques, driving up the installation costs.

Comparison of Average Siding Installation Costs

The table below provides a general comparison of average costs for installing different siding types. These are estimates and may vary based on specific circumstances.

| Siding Type | Average Cost per Square Foot (USD) |

|---|---|

| Vinyl | $3-$6 |

| Wood | $6-$10 |

| Fiber Cement | $8-$12 |

Estimating Siding Installation Costs

Accurately estimating siding installation costs is crucial for homeowners. A well-defined estimate helps avoid unpleasant surprises and ensures a smooth project execution. This involves not only calculating material costs but also factoring in labor, potential permits, and disposal fees. Proper planning prevents budget overruns and allows for informed decision-making.

Step-by-Step Process for Estimating Costs

A systematic approach to estimating siding installation costs ensures accuracy and minimizes potential errors. Begin by meticulously measuring the exterior surface area of the house requiring siding. This measurement serves as the foundation for material calculations. Next, determine the appropriate material quantities needed, considering factors like siding type and any required accessories. Finally, consult with contractors to obtain labor estimates, and factor in potential hidden costs like permits or disposal fees. Thoroughness in each step contributes to a precise and reliable estimate.

Measuring Surface Area of the House

Accurate measurement of the house’s surface area is paramount to a precise cost estimate. Use measuring tools like a tape measure and a level to obtain precise dimensions. Carefully record the measurements for each section of the house that requires siding. If the house has complex shapes or irregular features, consider breaking down the surface into smaller, manageable sections. This detailed approach ensures a precise total area, crucial for accurate material calculations.

Calculating Material Quantities

Calculating the exact amount of siding material needed ensures efficient resource utilization and avoids unnecessary purchases. This involves considering the siding’s linear footage and the total square footage of the area needing siding. Siding sheets or panels have specific dimensions. Divide the total surface area by the siding’s square footage per sheet or panel to determine the required number of units. Account for potential waste or breakage by adding a small contingency to the calculated quantity.

Importance of Accurate Measurements

Accurate measurements are essential for a precise cost estimate. Inaccurate measurements can lead to significant overspending on materials or, conversely, a shortage, necessitating additional purchases during the project. This can disrupt the timeline and increase the overall cost. A meticulously detailed measurement process, using accurate tools and a systematic approach, is crucial to a successful and cost-effective siding installation project.

Accounting for Hidden Costs

Hidden costs can significantly impact the overall project budget. Obtain quotes from local contractors for permits, if required, and for disposal fees. These costs are often overlooked and can add to the project’s total expenditure. Consider consulting with a local building department to determine if permits are necessary for your specific project. This proactive step safeguards against unforeseen expenses.

Sample Calculations for Different Siding Projects

| Project | Surface Area (sq ft) | Siding Type | Material Cost per sq ft | Labor Cost | Total Estimated Cost |

|---|---|---|---|---|---|

| Small House (1000 sq ft) | 1000 | Vinyl | $2.50 | $5,000 | $7,500 |

| Medium House (1500 sq ft) | 1500 | Fiber Cement | $4.00 | $7,500 | $11,000 |

| Large House (2000 sq ft) | 2000 | Wood | $3.50 | $10,000 | $17,000 |

These are illustrative examples and costs can vary based on local material prices, labor rates, and project complexity.

Comparing Siding Installation Quotes

Getting multiple siding installation quotes is crucial for ensuring you receive a fair price and high-quality work. Comparing quotes allows you to evaluate different contractor approaches, identify potential issues, and ultimately select the best option for your project. Understanding the factors involved in a thorough comparison is vital for a successful siding installation.

Thorough comparison of quotes is essential to make an informed decision. By evaluating various factors, including experience, licensing, insurance, timelines, warranties, and the overall value proposition, homeowners can confidently choose a contractor that meets their needs and budget. This process empowers you to select the most suitable contractor for your project, saving you time, money, and potential headaches.

Importance of Multiple Quotes

Obtaining multiple quotes is vital for a fair and transparent bidding process. It provides a range of options, enabling you to compare prices, services, and potential risks associated with each contractor. This competitive approach allows you to identify the best value proposition and potentially negotiate favorable terms.

Factors to Consider When Comparing Quotes

Several key factors should be considered when comparing siding installation quotes. Price is important, but other elements such as the contractor’s experience, licensing, and insurance should also be assessed. These elements provide insights into the contractor’s reliability and competence.

Identifying Potential Red Flags in Quotes

Reviewing quotes meticulously is essential to identify potential red flags. Unrealistic timelines, vague descriptions of materials, or missing details regarding warranties are red flags. Inconsistent or unclear pricing structures, a lack of detailed information about the work process, and the absence of contact information are also cause for concern. Look for quotes that provide detailed explanations of the process and materials, outlining the scope of work and the anticipated timeline.

Contractor Comparison Table

| Contractor | Experience (Years) | Licensing Status | Insurance Information | References |

|---|---|---|---|---|

| ABC Siding Solutions | 15 | Licensed and Insured | General Liability, Workers’ Compensation | Available upon request |

| XYZ Home Improvements | 8 | Licensed and Insured | General Liability, Workers’ Compensation | Available upon request |

| Pro Siding Pros | 10 | Licensed and Insured | General Liability, Workers’ Compensation | Available upon request |

This table provides a structured format for comparing different contractors based on their experience, licensing, and insurance. Additional information like references can further strengthen your evaluation process. Be sure to thoroughly verify the information provided by each contractor.

Analyzing Timelines and Warranties

Contractors’ proposed timelines should be carefully examined. Realistic schedules, clearly Artikeld steps, and milestones are important. Be cautious of overly optimistic or vague timelines. Warranty details are equally important. Thorough warranty explanations, covering the materials and workmanship, are critical. Look for specific language outlining the scope of coverage and the process for making claims. Detailed warranty information ensures clarity and protects your investment.

Evaluating the Overall Value Proposition

Ultimately, the best contractor is the one that offers the best value proposition. Consider all aspects of the quote, including price, experience, licensing, insurance, timelines, and warranties. Analyze the overall package to determine which contractor aligns best with your needs and budget. A comprehensive approach helps you identify the contractor that provides the most value for your money and ensures a successful project.

Siding Installation Cost Breakdown

A crucial aspect of any siding project is understanding the detailed cost breakdown. This allows homeowners to accurately budget and compare quotes, ensuring a transparent and informed decision-making process. Knowing the components of the installation cost helps manage expectations and avoid surprises.

The total cost for siding installation encompasses labor, materials, permits, and potential incidental expenses. Accurately estimating these costs is vital for a successful project. Different siding types, project sizes, and geographical locations will influence the final price.

Labor Costs

Labor costs represent a significant portion of the total installation price. These costs vary based on factors such as the complexity of the job, the amount of siding material, the crew size, and local labor rates. The process of installation is generally broken down into distinct phases.

- Site Preparation: This stage involves tasks like removing old siding, cleaning the surface, and preparing the wall for new siding. The labor cost is dependent on the extent of the prep work, including the time required for demolition, cleaning, and ensuring the wall’s structural readiness for the new siding.

- Siding Installation: This phase encompasses the actual application of the siding panels. The labor cost depends on the siding type, the complexity of the building’s structure, and the crew’s efficiency. For example, installing siding on a multi-story home or a complex architectural design will require more labor hours and potentially higher costs.

- Finishing Touches: This involves tasks like caulking, painting, and installing any necessary trim. The labor cost for these final steps is often a smaller percentage of the total labor cost but can still vary based on the extent of the finishing work.

Material Costs

Material costs comprise the expenses for the siding itself, including delivery, handling, and disposal of waste. The cost of materials is a major factor in the total project budget.

- Siding Material: The price per square foot varies significantly based on the type of siding (vinyl, fiber cement, wood, etc.), the brand, and the desired features. For example, a higher-end, premium vinyl siding will generally be more expensive than standard vinyl siding.

- Delivery and Handling: Delivery charges depend on the distance from the supplier, the quantity of materials, and any special handling requirements. Handling costs may be included in the material price or presented as a separate charge.

- Waste Disposal: Proper disposal of old siding and construction waste is essential. The cost of waste disposal is often factored into the overall project cost or can be arranged separately.

Permit and Inspection Costs

In some areas, permits and inspections are required for siding installations, especially for substantial projects. The costs for these vary based on local regulations and the scope of the project.

- Permit Fees: These fees are typically determined by local building codes and vary based on the type and extent of the work.

- Inspection Fees: Inspections are essential to ensure the installation complies with local codes and regulations. The fees associated with these inspections are often predetermined by the jurisdiction.

Hidden or Incidental Costs

Unexpected costs can arise during the installation process. These could include additional materials needed due to unforeseen issues, adjustments to the project scope, or extra labor hours required for complex situations.

- Additional Materials: Unforeseen damage to the existing structure or unexpected changes to the project design may necessitate additional materials. This could include additional fasteners, trim pieces, or other items.

- Weather Delays: Unfavorable weather conditions can impact the timeline and potentially increase labor costs.

- Project Modifications: Modifications to the original plan might require extra labor or materials.

Sample Cost Breakdown (Vinyl Siding)

| Category | Estimated Cost |

|---|---|

| Labor (Site Prep, Installation, Finishing) | $3,500 |

| Materials (Vinyl Siding, Accessories) | $2,800 |

| Delivery & Handling | $200 |

| Permit & Inspection | $150 |

| Waste Disposal | $50 |

| Total Estimated Cost | $6,700 |

Influence of Local Market Conditions on Costs: Siding Installation Cost

Local market conditions play a significant role in shaping the cost of siding installation. These factors, encompassing material availability, labor market dynamics, seasonal variations, economic fluctuations, and local regulations, all contribute to the final price tag. Understanding these influences is crucial for homeowners seeking accurate estimates and informed decisions.

Material Availability and Demand

Material availability and demand directly impact siding installation costs. High demand for specific siding types, coupled with limited supply, often leads to price increases. For instance, if a popular type of cedar siding is in short supply due to a recent forest fire, the cost of this material will likely rise, consequently increasing the overall installation cost. Conversely, ample supply of readily available materials, like vinyl siding, can keep costs relatively stable.

Labor Market Conditions

Labor market conditions significantly influence siding installation costs. Regions with a shortage of qualified installers or high demand for their services will typically command higher wages. This translates to a higher price for the installation itself. Conversely, regions with an abundant supply of installers may result in lower labor costs. For example, a booming construction sector in a particular area may drive up wages for siding installers.

Seasonal Factors

Seasonal factors, primarily weather conditions, can also affect siding installation costs. Extreme weather events like severe storms or prolonged periods of extreme heat or cold can impact the schedule and necessitate extra precautions, leading to increased labor costs. In addition, certain seasons may see a higher demand for siding installations, influencing prices. For example, in areas with harsh winters, homeowners often opt for siding installations in the spring and fall, leading to a seasonal surge in demand.

Economic Fluctuations

Economic fluctuations can affect the prices of siding materials and labor. During periods of economic downturn, the cost of materials may decrease as demand falls. However, labor costs might also be impacted by economic trends. During periods of economic growth, the demand for siding installations may increase, along with labor costs. For instance, a general economic boom may result in higher wages for siding installers, while a recession might cause the price of raw materials to decrease.

Local Building Codes and Regulations

Local building codes and regulations can impact siding installation costs. Stricter regulations regarding energy efficiency or specific installation methods may necessitate additional materials or labor, thus increasing the project cost. For example, building codes requiring specific types of insulation behind siding will lead to higher installation costs.

Regional Cost Variations

| Region | Typical Variation in Siding Installation Costs (USD per square foot) |

|---|---|

| Northeastern US | $10-$15 |

| Midwestern US | $8-$12 |

| Southern US | $7-$11 |

| Western US | $9-$14 |

The table above provides a general idea of typical variations in siding installation costs across different regions. However, these figures are estimates and may differ based on specific project requirements and local market conditions. Other factors, such as the type of siding, the complexity of the installation, and the size of the project, also influence the final cost.

Choosing the Right Siding Material

Selecting the appropriate siding material is crucial for both the initial cost and the long-term performance of your home. This decision significantly impacts the aesthetics, durability, and maintenance requirements of your property. Different materials offer unique advantages and disadvantages, influencing the overall cost of the project. Careful consideration of these factors will guide you towards a siding choice that meets your needs and budget.

Understanding the diverse range of siding materials available is essential for making an informed decision. Each material possesses a unique set of characteristics, affecting the overall project cost and long-term value. From the initial installation to potential future repairs and replacements, the material choice plays a pivotal role.

Comparing Siding Materials and Their Costs

Different siding materials offer varying degrees of durability, aesthetic appeal, and maintenance requirements. Understanding these differences is crucial for choosing the right material for your specific needs. Factors like budget, desired aesthetics, and local climate conditions influence the optimal selection.

- Vinyl Siding: Vinyl siding is a popular choice due to its affordability and low maintenance. Its resistance to rot, insects, and extreme weather conditions makes it a reliable option. However, it may not be as aesthetically diverse as other materials. Vinyl siding installation costs typically fall within the mid-range, influenced by factors like material quality, labor costs, and the complexity of the installation.

- Wood Siding: Wood siding offers a classic, natural aesthetic. Its warmth and beauty are appealing to many homeowners. However, wood requires regular maintenance, including painting or staining, to prevent decay and insect damage. Installation costs for wood siding are generally higher than vinyl, reflecting the higher labor demands and the need for specialized finishing. The cost can vary considerably depending on the type of wood used (e.g., cedar, pine) and the complexity of the design.

- Fiber Cement Siding: Fiber cement siding combines the durability of cement with the aesthetic appeal of wood. It resists rot, insects, and fire, offering long-term value. However, fiber cement siding typically has a higher upfront cost compared to vinyl or wood. Installation costs are generally higher than vinyl, reflecting the material’s inherent strength and the need for specialized installation techniques.

Factors to Consider When Selecting Siding Material

Several factors influence the optimal choice of siding material. These factors include budget constraints, desired aesthetics, local climate conditions, and long-term maintenance considerations. Considering these elements will help you make a decision that aligns with your project’s goals.

- Budget: The initial cost of the material and installation plays a crucial role. Vinyl siding tends to be the most budget-friendly option, while fiber cement siding typically has the highest upfront cost.

- Aesthetics: Consider the desired visual appeal of your home. Wood siding offers a classic look, while vinyl siding provides a modern alternative. Fiber cement siding can emulate the appearance of wood or other materials.

- Climate: The local climate conditions influence the material’s suitability. Areas with high humidity or frequent storms may require more durable siding materials.

- Maintenance Requirements: Assess the time and effort you’re willing to dedicate to maintaining the siding. Vinyl siding requires minimal maintenance, while wood siding demands regular upkeep.

Durability, Maintenance, and Aesthetic Comparison

The following table provides a concise comparison of different siding materials based on their durability, maintenance requirements, and aesthetic qualities. This overview helps to weigh the pros and cons of each material type.

| Siding Material | Durability | Maintenance | Aesthetics |

|---|---|---|---|

| Vinyl | Good; resists rot, insects, and weather | Low; minimal upkeep | Modern, various colors and styles |

| Wood | Good; requires regular maintenance | High; needs painting or staining | Classic, natural, warm |

| Fiber Cement | Excellent; highly durable | Medium; requires occasional cleaning | Versatile; can mimic wood or other styles |

Environmental Impact of Siding Materials

The environmental impact of siding materials varies. Consider the sourcing, manufacturing processes, and potential for recycling when evaluating the environmental footprint of each material. This information is essential for sustainable building practices.

- Vinyl Siding: Vinyl siding production can involve energy-intensive processes. Recycling options are available, but participation rates may vary.

- Wood Siding: Sustainable forestry practices are crucial to minimize the environmental impact of wood siding. Wood siding’s renewable nature is a significant advantage.

- Fiber Cement Siding: Fiber cement siding production often involves using cement, which can have an environmental impact. Proper disposal and recycling of the material are crucial.

Impact of Material Quality on Long-Term Costs

The quality of the siding material significantly impacts long-term costs. Higher-quality materials may have a higher upfront cost, but they often result in reduced maintenance and replacement needs over time. This factor is critical in assessing the overall value proposition of different siding materials. Consider the warranty and the reputation of the manufacturer when evaluating the quality of the siding.

Tips for Saving Money on Siding Installation

Maximizing your budget while ensuring a quality siding installation requires strategic planning and proactive measures. Understanding the factors influencing cost, from material selection to contractor negotiation, is key to achieving cost-effective results. This section details actionable strategies for minimizing expenses without compromising the longevity or aesthetics of your siding.

Finding Discounts and Deals on Siding Materials

Various avenues can lead to substantial savings on siding materials. Checking for manufacturer rebates and promotions is often overlooked. Building material retailers and wholesalers frequently offer discounts, especially during off-peak seasons or for bulk purchases. Online marketplaces and comparison websites can aid in identifying the best deals on siding products. A thorough search for discounts and deals can significantly reduce material costs.

Choosing Contractors with Competitive Pricing

Selecting a contractor with competitive pricing is essential. Requesting multiple quotes from reputable contractors is a critical step. Comparing quotes based on not just the total cost, but also the breakdown of labor, materials, and any additional fees, is crucial. Evaluating contractor experience and reputation, while crucial, should be coupled with a meticulous comparison of their pricing structure. This approach ensures a fair assessment of the value proposition.

Benefits of Using Pre-approved Vendors or Contractors

Pre-approved vendors or contractors often offer competitive rates. These relationships are built on trust and established processes, allowing for streamlined communication and efficient project management. By leveraging pre-approved networks, homeowners can potentially secure better pricing through established agreements or volume discounts.

Avoiding Costly Mistakes During Installation

Preventing errors during installation is paramount for minimizing expenses. Thorough planning, including site preparation and accurate measurements, can significantly reduce the potential for costly revisions or rework. Communicating clearly with the contractor regarding project scope and expectations minimizes misunderstandings and potential disputes. Adhering to the agreed-upon schedule and timelines also avoids extra costs associated with delays.

Negotiating Prices with Contractors

Negotiation is a valuable tool for achieving favorable pricing. Presenting a clear understanding of the project, budget constraints, and desired outcomes empowers you to discuss options with contractors. Demonstrating a comprehensive knowledge of your project, including material choices and potential complexities, can allow for a more productive negotiation. Being prepared to walk away if necessary is a strong negotiating tactic.

Potential Savings Opportunities

| Savings Opportunity | Description | Estimated Savings Potential |

|---|---|---|

| Negotiated Discounts | Bargaining with contractors for reduced labor or material costs. | 5-15% |

| Bulk Material Purchases | Ordering larger quantities of materials for potential volume discounts. | 3-10% |

| Seasonal Sales | Taking advantage of discounts offered during off-peak seasons. | 5-15% |

| Pre-approved Vendor Discounts | Leveraging relationships with pre-approved vendors. | 5-10% |

| Efficient Planning and Preparation | Minimizing rework and delays by precise planning and measurements. | Variable, but potentially significant |

Closure

Source: homedit.com

In conclusion, determining the precise siding installation cost requires careful consideration of numerous factors. By understanding material costs, labor rates, regional variations, and potential hidden expenses, you can confidently estimate and manage your project budget. Comparing quotes, analyzing contractor details, and understanding local market influences are all key steps in making an informed decision. Ultimately, this guide equips you with the knowledge and tools to choose the right siding material and installation process, ensuring a successful and cost-effective home improvement project.